Finding the best warehouse management systems can transform your business operations, reduce labor costs, and dramatically improve order accuracy.

Whether you’re managing a single fulfillment center or a complex distribution center network, the right warehouse management solution delivers real-time inventory visibility, streamlined warehouse processes, and the automation you need to stay competitive.

This comprehensive guide examines the best warehouse management system options in 2025, comparing features, pricing, use cases, and integration capabilities. By the end, you’ll know exactly which WMS system aligns with your business needs.

What Is a Warehouse Management System?

A warehouse management system (WMS) is software that manages and optimizes warehouse operations from receiving and putaway to order picking, packing, and shipping. Modern WMS platforms provide real-time inventory tracking, automated workflows, labor management, and seamless integration with enterprise resource planning (ERP), transportation management systems, and eCommerce platforms.

The best warehouse management systems go beyond basic inventory control to offer advanced capabilities like wave planning, cross-docking, yard management, and machine learning-driven demand forecasting.

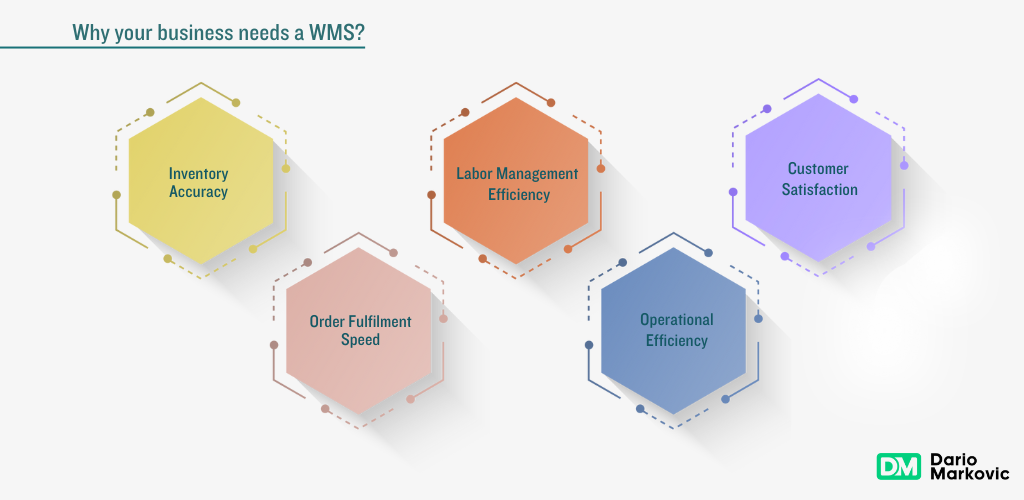

Why Your Business Needs a WMS?

Manual warehouse processes create bottlenecks, inventory accuracy issues, and costly human error.

Implementing warehouse management system software delivers measurable benefits for growing businesses:

- Inventory Accuracy: Real-time data tracking reduces stock discrepancies from industry averages of 63% accuracy to 99%+ with barcode scanners and RFID technology, preventing stockouts and excess stock levels.

- Labor Management Efficiency: Task optimization and directed putaway/order picking can increase productivity by 25-40%, allowing your team to handle higher order volumes with the same headcount while reducing labor costs.

- Order Fulfillment Speed: Automated picking strategies and optimized warehouse space layouts reduce order processing cycle times by up to 30%, improving the fulfillment process.

- Operational Efficiency: Better warehouse efficiency, reduced picking errors, and optimized workflows typically deliver strong return on investment within 12-18 months.

- Customer Satisfaction: Improved order accuracy and faster shipping lead to better customer service, fewer returns, and enhanced customer experience across all sales channels.

How We Evaluated the Best Warehouse Management Systems

Our evaluation focused on the criteria that matter most when selecting warehouse management solution options:

- Scalability: Ability to grow from single to multi-warehouse locations

- Integration capabilities: Seamless connectivity with accounting systems, eCommerce platforms, and shipping carriers

- Ease of use: Intuitive interfaces compatible with mobile devices and smartphones that reduce training time

- Automation features: Support for warehouse automation, robotics, and AI optimization

- Real-time visibility: Comprehensive dashboards providing real-time updates

- Mobile functionality: Robust apps for on-the-floor supply chain operations

- Pricing transparency: Clear total cost structures without hidden fees

- Customer service: Availability, quality, and responsiveness

- Industry-specific features: Specialized capabilities for various supply chain management needs

12 Best Warehouse Management Systems in 2025

1. Manhattan Active WMS

Best for: Enterprise Operations and Omnichannel Fulfillment

Manhattan Active WMS leads the enterprise market with its cloud-based warehouse management system architecture and continuous innovation model. Manhattan Associates delivers new features automatically through its “always current” approach, making it one of the best WMS platforms for large-scale operations.

Key Features:

- AI-powered wave planning and task optimization using machine learning

- Advanced robotics orchestration supporting warehouse automation

- Native omnichannel fulfillment capabilities across sales channels

- Micro-fulfillment center support for distribution centers

- Real-time labor management with gamification

- Comprehensive yard management

- 3D visual warehouse modeling

Ideal For: Large enterprises, third-party logistics (3PL) providers managing multiple clients, retailers with complex omnichannel requirements, and operations requiring sophisticated warehouse automation.

Pricing: Custom enterprise pricing, typically starting at $100,000+ annually. Implementation costs range from $250,000 to several million depending on complexity.

Pros:

- Industry-leading functionality depth for operational efficiency

- Continuous updates without disruptive upgrades

- Exceptional warehouse automation capabilities

- Strong analytics and AI-driven optimization for supply chain execution

Cons:

- Premium pricing puts it out of reach for small business operations

- Complex implementation requiring significant human resources

- Steep learning curve for basic users

2. Blue Yonder Warehouse Management

Best for: Complex Distribution Networks

Blue Yonder brings decades of supply chain management expertise to its warehouse management solution, with particular strength in network optimization and demand-driven fulfillment strategies for distribution centers.

Key Features:

- Integrated labor management with AI scheduling

- Dynamic slotting optimization for warehouse space

- Machine learning-based demand forecasting integration

- Advanced cross-docking capabilities for fulfillment centers

- Transportation and warehouse coordination

- Configurable workflows without custom coding

- Robust API framework for integration capabilities

Ideal For: Manufacturers with distribution networks, grocery and food distributors, retailers with regional distribution centers, and companies prioritizing supply chain efficiency.

Pricing: Enterprise-level pricing with costs comparable to Manhattan Active, typically $80,000-$150,000+ annually depending on modules and warehouse locations.

Pros:

- Excellent for complex network optimization and supply chain operations

- Strong integration with broader Blue Yonder supply chain solutions

- Powerful slotting and warehouse space optimization

- Proven scalability for global operations

Cons:

- Requires substantial implementation timeline

- Interface feels less modern than newer competitors

- Best value realized when using multiple Blue Yonder products

3. Oracle Warehouse Management Cloud

Best for: Oracle ERP Users and Mid-to-Large Enterprises

Oracle WMS Cloud offers native integration with Oracle’s business processes while remaining flexible enough to integrate with other enterprise resource planning systems. Its cloud-based design delivers enterprise capabilities with lower infrastructure costs.

Key Features:

- Embedded mobility with iOS and Android mobile devices

- RF smart scanning technology with barcode scanners

- Configurable wave planning and task management

- Advanced quality control management

- Comprehensive 3PL billing capabilities for third-party logistics

- Value-added services management

- Kitting and assembly operations support

Ideal For: Companies using Oracle Cloud ERP, third-party logistics needing sophisticated billing, manufacturers with complex value-added services, and organizations requiring strong financial integration with accounting systems.

Pricing: Subscription-based pricing starting around $3,000-$5,000 per month for smaller implementations, scaling with transaction volume and users. Implementation costs typically range from $50,000-$300,000.

Pros:

- Seamless Oracle ecosystem integration for business processes

- Strong 3PL and billing capabilities

- Regular cloud updates and improvements with real-time updates

- Good functionality for mobile devices

Cons:

- Can be overly complex for simple operations

- Implementation requires Oracle expertise

- Less intuitive than some newer WMS platforms

4. SAP Extended Warehouse Management (EWM)

Best for: SAP Users and Manufacturing Operations

SAP EWM extends SAP’s ERP dominance into warehouse operations with deep integration and sophisticated functionality for complex manufacturing and supply chain management environments.

Key Features:

- Embedded in SAP S/4HANA for real-time processing

- Advanced warehouse automation integration

- Cross-docking and flow-through distribution for fulfillment centers

- Batch management and serial numbers tracking

- Hazardous materials handling with quality control

- Integrated quality inspection processes

- Resource and labor management optimization

Ideal For: Existing SAP customers, manufacturers with complex material flows, companies handling regulated materials, and organizations requiring tight ERP-WMS integration for business needs.

Pricing: Licensing costs vary significantly based on users and deployment model. Cloud pricing starts around $5,000-$10,000 monthly, while on-premise implementations can require $200,000+ in licenses plus implementation costs of $300,000-$1,000,000+.

Pros:

- Unmatched SAP integration with enterprise resource planning

- Extremely robust for manufacturing scenarios

- Handles complex business processes and compliance

- Powerful real-time data processing

Cons:

- Requires SAP expertise for implementation and management

- Complex and resource-intensive

- High total cost of ownership

- Overwhelming for non-SAP environments

5. Deposco Bright Warehouse

Best for: Omnichannel Retailers and E-commerce

Deposco positions itself as supply chain solutions software with particular strength in unifying warehouse management with order management and inventory management system capabilities for omnichannel fulfillment.

Key Features:

- Unified platform combining WMS software, order management, and inventory control

- Real-time inventory visibility across sales channels

- Dynamic order routing and allocation

- Dropship and vendor management

- Native eCommerce platforms integrations

- Built-in shipping carriers management

- Cloud-based warehouse management system with rapid deployment

Ideal For: Omnichannel retailers, direct-to-consumer brands, companies managing both warehouses and dropship vendors, and growing businesses prioritizing speed to value.

Pricing: Subscription-based with pricing scaling on order volumes, typically starting around $2,000-$4,000 monthly for smaller operations. Implementation is generally faster and less expensive than enterprise systems, ranging from $25,000-$100,000.

Pros:

- Quick implementation timeframe

- Excellent omnichannel capabilities for customer experience

- User-friendly modern interface

- Strong eCommerce platforms integrations out of the box

Cons:

- Less suitable for complex manufacturing scenarios

- Limited advanced warehouse automation support compared to enterprise leaders

- Smaller customer base than established enterprise vendors

6. HighJump (Körber Supply Chain WMS)

Best for: Mid-Market Companies and 3PLs

Körber’s HighJump WMS serves the mid-market with enterprise-grade functionality at more accessible price points, offering strong flexibility and comprehensive third-party logistics capabilities.

Key Features:

- Configurable workflows without coding

- Voice-directed order picking integration

- Comprehensive yard management

- 3PL billing and customer portal

- Labor management and performance tracking

- Multi-client and multi-warehouse locations support

- Strong API and integration capabilities framework

Ideal For: Mid-sized distributors and manufacturers, third-party logistics serving multiple clients, companies using voice-directed operations, and organizations needing flexibility without enterprise complexity.

Pricing: More accessible than top-tier enterprise systems, with licensing typically ranging from $50,000-$150,000 plus implementation costs of $75,000-$250,000 depending on requirements and customization.

Pros:

- Good balance of functionality and total cost

- Proven track record with mid-market companies

- Flexible configuration options

- Strong 3PL features for party logistics operations

Cons:

- Interface feels dated compared to newer cloud-based warehouse management systems

- Implementation can still be complex

- Less innovation momentum than cloud-native competitors

7. Fishbowl Warehouse

Best for: Small-to-Mid-Sized Manufacturers

Fishbowl delivers manufacturing-focused warehouse management solution integrated tightly with QuickBooks accounting software, making it ideal for growing businesses outgrowing basic inventory software but not ready for enterprise WMS system complexity.

Key Features:

- Native QuickBooks integration with accounting systems

- Manufacturing order management and sales orders

- Bill of materials and work order tracking

- Barcode scanner technology and mobile devices apps

- Multi-location inventory management across warehouse locations

- Basic automation support

- Purchase orders and vendor management

Ideal For: Small business manufacturers using QuickBooks, companies with 1-5 warehouse locations, businesses combining manufacturing and distribution, and organizations with limited IT human resources.

Pricing: One-time licensing starting around $4,000-$8,000 depending on modules and users, plus annual support fees of approximately 20% of license costs. Implementation and training typically add $5,000-$20,000.

Pros:

- Affordable entry point for small business operations

- Excellent QuickBooks integration

- Straightforward implementation

- Good manufacturing capabilities for the price point

Cons:

- Limited scalability for high-growth companies

- Basic warehouse automation and optimization features

- On-premise deployment model requires local tech stack infrastructure

- Not suitable for complex multi-warehouse locations networks

8. Infor WMS (CloudSuite WMS)

Best for: Industry-Specific Requirements

Infor WMS built its reputation on industry-specific software solutions, and its CloudSuite WMS delivers tailored functionality for fashion, automotive, food and beverage, and other specialized supply chain management sectors.

Key Features:

- Industry-specific workflows and templates

- Advanced slotting and replenishment for inventory levels

- Quality control and lot tracking with expiration date management

- Integrated labor management

- Yard management and dock scheduling

- Wave and task management for operational efficiency

- Mobile RF applications for mobile devices

Ideal For: Fashion and apparel distributors, automotive parts suppliers, food and beverage operations, and companies requiring industry-specific compliance and warehouse processes.

Pricing: Cloud subscription model with pricing typically ranging from $40,000-$120,000 annually depending on transaction volumes and modules. Implementation costs generally fall between $75,000-$300,000.

Pros:

- Deep industry expertise and pre-configured workflows

- Part of broader Infor CloudSuite for full supply chain solutions coverage

- Modern cloud-based architecture

- Strong international customer service support

Cons:

- Can be complex for straightforward operations

- Implementation timelines can be lengthy

- Best value for companies needing industry-specific features

9. Logiwa WMS

Best for: High-Volume E-commerce Fulfillment

Logiwa targets high-growth eCommerce platforms and third-party logistics with a cloud-based warehouse management system designed for rapid deployment and seamless integration with eCommerce platforms.

Key Features:

- Pre-built integrations with major eCommerce platforms and online stores

- Real-time inventory visibility synchronization

- Multi-channel order management across sales channels

- Dynamic order picking optimization

- Integrated shipping and shipping carriers management

- Customer portal for party logistics providers

- Mobile-first design for mobile devices

Ideal For: E-commerce fulfillment operations, direct-to-consumer brands, 3PLs focused on online stores clients, and growing businesses prioritizing integration speed and ease of use.

Pricing: Subscription pricing based on order volumes, typically starting around $1,500-$2,500 monthly for smaller operations and scaling up. Implementation is comparatively fast and less expensive, often $10,000-$40,000.

Pros:

- Rapid deployment timeframes

- Excellent eCommerce platforms integrations

- Intuitive user interface

- Strong functionality for mobile devices

- Responsive customer service support

Cons:

- Less suitable for complex manufacturing

- Limited advanced warehouse automation orchestration

- Fewer legacy system integrations than established vendors

10. Cin7 Omni (formerly DEAR)

Best for: Small Businesses and Multi-Channel Retailers

Cin7 Omni provides an accessible entry point for small business needs requiring inventory management solution and basic warehouse capabilities combined with POS and eCommerce platforms integration.

Key Features:

- Unified inventory control across sales channels

- Basic warehouse system and pick/pack/ship workflows

- eCommerce platforms and POS integrations with online stores

- Purchase orders management

- B2B portal capabilities

- Manufacturing light features

- Accounting systems integration

Ideal For: Small business retail and e-commerce operations, companies selling through multiple sales channels, businesses with 1-2 warehouse locations, and organizations seeking affordable cloud inventory software.

Pricing: Subscription tiers starting around $300-$500 monthly for basic plans, scaling to $1,000+ for higher volumes and additional features. Free trial available. Implementation is typically self-service or minimal, keeping costs low.

Pros:

- Very affordable for small business operations

- Easy to implement and use

- Good channel integration breadth

- No long-term contracts with free trial option

Cons:

- Limited true WMS capabilities

- Not scalable for complex operations

- Basic warehouse automation and optimization features

- Customer service can be slower than enterprise vendors

11. ShipHero WMS

Best for: Direct-to-Consumer Brands and 3PL Fulfillment

ShipHero delivers a cloud-based warehouse management system purpose-built for eCommerce fulfillment, with strong capabilities for both brands managing their own fulfillment centers and third-party logistics providers.

Key Features:

- Native integrations with major eCommerce platforms and online stores

- Real-time inventory visibility across warehouse locations

- Advanced order picking workflows and wave planning

- Automated shipping labels generation with multiple shipping carriers

- Customer portal for order status tracking

- Cycle counting and inventory accuracy tools

- Mobile-first interface optimized for smartphones and mobile devices

Ideal For: Direct-to-consumer brands, third-party logistics providers, eCommerce companies managing their own fulfillment centers, and growing businesses during peak seasons.

Pricing: Subscription-based pricing starting around $1,500-$3,000 monthly depending on order volumes and warehouse locations. Free trial available. Implementation typically ranges from $5,000-$25,000.

Pros:

- Excellent for eCommerce fulfillment process optimization

- Strong real-time data and analytics

- Easy integration with major eCommerce platforms

- Responsive customer service and support

- Handles peak seasons order volumes efficiently

Cons:

- Limited features for traditional wholesale distribution

- Not ideal for complex manufacturing use cases

- Fewer enterprise resource planning integrations than larger platforms

12. ShipBob WMS

Best for: E-commerce Brands Seeking Fulfillment-as-a-Service

ShipBob offers a unique model combining warehouse management system software with fulfillment center services, allowing eCommerce brands to leverage ShipBob’s warehouse locations or use the WMS software independently.

Key Features:

- Cloud-based warehouse management system with real-time updates

- Integration with major eCommerce platforms and online stores

- Distributed inventory management across multiple warehouse locations

- Automated order processing and shipping labels

- Customer orders tracking and order status visibility

- Analytics dashboard showing real-time data

- Mobile app for smartphones management

Ideal For: E-commerce brands seeking fulfillment center solutions, small business operations wanting to outsource logistics processes, direct-to-consumer companies, and businesses testing new sales channels.

Pricing: Fulfillment service pricing varies by storage and order volumes. WMS software-only option available starting around $2,000 monthly. Free trial available for evaluation.

Pros:

- Flexible model: use fulfillment centers or software independently

- Multiple warehouse locations for distributed inventory

- Strong eCommerce platforms integrations

- Reduces guesswork with clear analytics

- Scales well for growing businesses

Cons:

- Primarily focused on eCommerce, not suitable for complex warehouse processes

- Limited customization compared to enterprise WMS platforms

- Best value when using both software and fulfillment services

- Not ideal for traditional distribution center operations

9 Key Features to Consider in Warehouse Management Systems

When evaluating the best warehouse management systems for your operation, prioritize features that align with your specific business needs and growth trajectory.

1. Inventory Management and Tracking

Real-time inventory visibility is non-negotiable. Look for systems supporting barcode scanner technology, RFID, and serial numbers tracking with cycle counting capabilities that maintain inventory accuracy without disruptive full counts. This prevents stockouts and maintains optimal stock levels.

2. Order Management and Fulfillment

Wave planning, batch picking, and zone order picking strategies directly impact fulfillment process speed. Advanced systems offer AI-driven picking optimization that adapts to changing customer orders profiles and order volumes.

3. Receiving and Putaway

Directed putaway based on product velocity, size, and affinity rules maximizes warehouse space utilization and order picking efficiency. Cross-docking capabilities eliminate unnecessary storage for fast-moving items.

4. Integration Capabilities

Your warehouse system must communicate seamlessly with existing tech stack including enterprise resource planning systems, eCommerce platforms, shipping carriers, and warehouse automation equipment. APIs, EDI, and pre-built connectors reduce integration complexity and total cost.

5. Mobile and Voice Technology

Warehouse managers and teams need mobile access through rugged mobile devices or smartphones. Voice-directed order picking increases hands-free productivity while reducing human error in high-volume operations.

6. Reporting and Analytics

Dashboards tracking KPIs like order processing cycle time, order accuracy, inventory levels turnover, and labor management productivity enable continuous improvement. Real-time data and demand forecasting help anticipate bottlenecks before they impact the fulfillment process.

7. Automation Support

If you’re implementing or planning warehouse automation like conveyors, sorters, or robotics, ensure your WMS software can orchestrate these systems effectively. The best warehouse management systems coordinate human and automated tasks seamlessly for operational efficiency.

8. Labor Management

Track individual and team productivity, set standards, and create incentive programs that motivate without burning out your workforce. Time and attendance integration with human resources systems streamlines payroll.

9. Scalability

Your warehouse management solution should accommodate growth from single to multiple warehouse locations, increasing SKU counts, and higher order volumes without requiring complete replacement.

Types of Warehouse Management Systems

Understanding the types of warehouse management systems helps narrow your search based on business needs:

Standalone WMS: Dedicated WMS software focused exclusively on warehouse operations, offering deep functionality without requiring full supply chain management suites.

ERP-Integrated WMS: Warehouse management system software embedded within enterprise resource planning platforms like SAP or Oracle, providing tight integration with financial and business processes.

Cloud-Based WMS: Software-as-a-service WMS platforms offering lower upfront costs, automatic updates, and accessibility from any location, ideal for operations with multiple warehouse locations.

Supply Chain Execution Suites: Comprehensive platforms combining WMS with transportation management systems, labor management, and yard management for complete supply chain execution.

Cloud vs. On-Premise Warehouse Management Systems

The deployment model significantly impacts total cost, flexibility, and long-term viability.

Cloud-Based Warehouse Management System Benefits:

- Lower upfront costs with subscription pricing

- Regular automatic updates and new features

- Reduced IT infrastructure requirements

- Faster implementation timelines

- Better disaster recovery and business processes continuity

- Easier multi-warehouse locations management

- Access via mobile devices and smartphones from anywhere

On-Premise WMS Benefits:

- Full control over customization and real-time data

- No ongoing subscription fees after initial purchase

- May be required for specific security or compliance business needs

- Can work in facilities with limited internet connectivity

Most organizations now choose cloud-based warehouse management systems for flexibility and total cost of ownership advantages, according to industry research from Markets and Markets. On-premise systems increasingly serve only specialized scenarios with unique requirements.

Implementation Considerations for WMS Success

Selecting the best warehouse management system is only the first step. Successful implementation requires careful project management and change management.

Timeline Expectations

Implementation timelines vary dramatically by warehouse system complexity:

- Basic cloud-based warehouse management system: 1-3 months

- Mid-market systems: 3-6 months

- Enterprise WMS platforms: 6-18+ months

Rushing implementation leads to configuration errors, inadequate training, and poor adoption.

Change Management

Your warehouse managers and floor teams make or break WMS system success. Involve supervisors early, communicate benefits clearly, and provide comprehensive training. Address concerns proactively and celebrate early wins.

Data Migration

Clean, accurate real-time data is essential. Dedicate time to auditing inventory levels records, location management data, and product information before migration. Garbage in, garbage out applies forcefully to WMS implementations.

Testing and Go-Live Strategy

Comprehensive testing including integrated systems prevents go-live surprises. Consider phased rollouts by warehouse section or product category rather than big-bang approaches that risk operational efficiency disruption.

Best Practices for Warehouse Management Success

Following warehouse management best practices maximizes your return on investment:

- Start with process optimization: Fix broken warehouse processes before automating them

- Prioritize inventory accuracy: Regular cycle counting maintains reliable stock levels

- Leverage real-time data: Make decisions based on real-time inventory visibility, not guesswork

- Train thoroughly: Invest in comprehensive training for warehouse managers and staff

- Monitor KPIs: Track order accuracy, fulfillment process speed, and operational efficiency

- Integrate systems: Ensure seamless integration with eCommerce platforms, accounting systems, and shipping carriers

- Plan for peak seasons: Test your warehouse system’s capacity before high-volume periods

- Maintain quality control: Implement checks throughout the fulfillment process

How to Choose the Best Warehouse Management System for Your Business

Follow this framework to narrow your options and make a confident decision:

1. Define Your Business Needs

Document current pain points, desired capabilities, must-have versus nice-to-have features, and growth projections for the next 3-5 years. Consider your sales channels, order volumes, and warehouse locations.

2. Establish Your Budget

Consider total cost of ownership including software licensing, implementation services, hardware requirements (barcode scanners, mobile devices), training, and ongoing customer service. Factor in potential return on investment through reduced labor costs, improved inventory accuracy, and increased operational efficiency.

3. Create a Shortlist

Based on your size, industry, and business needs, narrow options to 3-5 warehouse management systems. Use this guide’s recommendations as a starting point. Many vendors offer a free trial for evaluation.

4. Request Demonstrations

See WMS platforms in action with your actual use cases. Involve warehouse managers and key users in demos. Evaluate interface usability on mobile devices and whether workflows match your warehouse processes.

5. Check References

Speak with current customers in your industry and similar size. Ask about implementation challenges, ongoing customer service quality, and whether the warehouse system delivered promised benefits. Request case study examples.

6. Evaluate Vendors

Consider vendor stability, financial health, customer base size, and innovation trajectory. Review Gartner’s Magic Quadrant for Warehouse Management Systems for independent vendor assessments. You’re entering a long-term partnership, so vendor reliability matters as much as software solutions features.

7. Review Contracts Carefully

Understand what’s included in pricing, costs for additional users or transactions, upgrade fees, and contract termination clauses. Check if a free trial is available.

ROI Timeline and Expectations

Most organizations see positive return on investment from the best warehouse management systems within 12-24 months through:

- Labor costs savings: 15-30% productivity improvement through better labor management

- Inventory control reduction: 10-25% decrease in required working capital by optimizing stock levels

- Accuracy improvements: Reduction in mis-ships from 2-3% to under 0.5%, improving order accuracy

- Space optimization: 10-30% better warehouse space utilization through improved slotting

- Expedited shipping reduction: Fewer rush shipments needed to meet customer orders commitments

- Improved customer satisfaction: Better customer service through accurate, on-time deliveries

Calculate your specific return on investment by quantifying current costs in these areas and applying conservative improvement percentages based on vendor references and case study data. Industry research from G2 provides additional benchmarking data for realistic ROI projections.

Future Trends in Warehouse Management Systems

The best WMS platforms continue evolving with emerging technologies:

Artificial Intelligence and Machine Learning: Predictive analytics optimize slotting, labor management scheduling, and demand forecasting. AI-driven order picking route optimization adapts in real-time to changing conditions.

Robotics Integration: Collaborative robots and autonomous mobile robots work alongside human teams, with WMS software orchestrating tasks between human and automated workers for warehouse automation.

Computer Vision: Camera-based systems supplement or replace barcode scanner technology for faster receiving and quality control. Dimensioning systems capture product measurements automatically.

Digital Twins: Virtual warehouse models enable testing layout changes, warehouse automation scenarios, and warehouse processes improvements before physical implementation.

IoT Sensors: Smart sensors monitor warehouse conditions, track asset locations, and provide real-time updates on equipment status and inventory levels.

Blockchain Integration: Supply chain solutions transparency and authentication capabilities are beginning to integrate with warehouse operations for high-value or regulated products.

Ready to Transform Your Warehouse Operations?

Choosing among the best warehouse management systems is a critical decision that impacts your operational efficiency, customer satisfaction, and bottom line. The right warehouse management solution eliminates guesswork, reduces human error, and positions your business for sustainable growth.

Whether you’re a small business outgrowing spreadsheets and basic inventory software, a growing business scaling rapidly across sales channels, or an enterprise replacing legacy systems, the perfect WMS system exists for your requirements and budget.

Take Action Today:

- Download our WMS Comparison Checklist to evaluate systems against your specific business needs

- Request demos from 3-5 vendors that align with your warehouse locations, order volumes, and integration requirements

- Schedule a consultation with our supply chain experts to discuss your unique challenges and get personalized recommendations

- Start a free trial with leading WMS platforms to experience real-time inventory visibility and operational efficiency firsthand

Don’t let outdated warehouse processes hold your business back. The most successful implementations start with clear objectives, involve warehouse managers and key stakeholders early, and recognize that technology alone doesn’t drive results, combining the right warehouse system with optimized logistics processes and engaged teams does.

Contact Dario Markovic today to schedule your personalized WMS assessment and discover which solution delivers the best return on investment for your operation.

The efficiency gains, inventory accuracy improvements, and competitive advantages await on the other side of successful WMS implementation.

FAQs About Warehouse Management Systems

What is the difference between a WMS and an inventory management system?

A warehouse management system focuses on optimizing warehouse operations including order picking, labor management, and warehouse space utilization within physical fulfillment centers. An inventory management system tracks stock levels and inventory control across all locations but lacks detailed warehouse processes functionality like directed putaway, wave planning, and yard management. The best warehouse management systems include inventory tracking plus operational optimization features.

How much does a warehouse management system cost?

WMS system costs vary significantly by size and complexity. Small business cloud-based warehouse management systems start around $300-$2,000 monthly with minimal implementation costs. Mid-market WMS platforms typically range from $3,000-$10,000 monthly plus $50,000-$300,000 implementation.

Enterprise systems like Manhattan Active and Blue Yonder start at $80,000-$100,000+ annually with implementation costs from $250,000 to over $1 million.

Total cost includes software licenses, implementation, hardware (barcode scanners, mobile devices), training, and ongoing customer service.

Can small businesses benefit from warehouse management systems?

Absolutely. Growing businesses often see the biggest relative gains from implementing warehouse management solutions. Even basic WMS software eliminates manual warehouse processes, reduces stockouts and human error, improves order accuracy, and provides real-time inventory visibility.

Many vendors like Cin7 Omni, Fishbowl, and Zoho Inventory offer affordable options under $1,000 monthly with free trial periods, making warehouse management accessible for small business operations with 1-3 warehouse locations.

How long does WMS implementation take?

Implementation timelines depend on the types of warehouse management systems and complexity. Simple cloud-based warehouse management systems with standard eCommerce platforms integrations can go live in 1-3 months.

Mid-market WMS platforms with custom workflows and enterprise resource planning integration typically require 3-6 months. Enterprise systems for complex distribution centers with extensive warehouse automation and multiple warehouse locations often need 6-18+ months.

Proper project management, clean real-time data, and strong change management accelerate successful implementations.

What integrations are most important for a WMS?

Essential integration capabilities include eCommerce platforms (for online stores and sales orders), accounting systems (for financial business processes), shipping carriers (for automated shipping labels), barcode scanners and mobile devices (for real-time data collection), and enterprise resource planning systems (for unified business needs).

Growing businesses should prioritize WMS platforms offering pre-built integrations with their current tech stack to reduce implementation complexity and total cost while ensuring seamless real-time updates across supply chain operations.